Torlon® High Performance Thermoplastic Composite Material

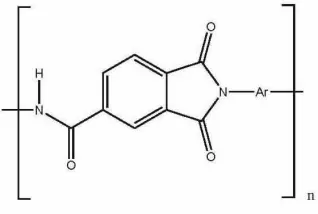

All Marketing Master’s clip nuts, press-fit inserts and potted-in inserts are made from a Composite material called Torlon®, our secret ingredient. Made from Solvay Advanced Polymers’ Torlon® is a high performance thermoplastic composite material, with the advantages of being corrosion-free, light weight, high strength, and less expensive than Stainless steel and titanium.

For more information on Torlon® thermoplastic composites, click on the link below.

What is high strength Torlon®,? What Industries and applications is Torlon® used? What is it made out of? How does it compare against other plastics and metal?

A breakdown of the many benefits of a Torlon® composite fasteners over metal fasteners: corrosion resistance, high strength, light weight, flame resistant, performs up to 500°F, is chromate free and less expensive.

Torlon® is Chromate Free.

Recent EPA and European Union regulations mandate that all clip nuts and fasteners for aircraft and other applications must be free of chromium and/or chromate. We take a look at why and how Marketing Masters’ Torlon® composite fasteners fully comply with the new regulations.

Torlon® engineering polymers have been successfully tested and approved by:

- UL

- FAA

- MIL-Spec

- NASA

- SAE

- AMS

- Airbus

- Bombardier

- Boeing...

For strong, non-corrosive, light weight & less expensive Torlon® composite fastener clip nuts, and inserts, Contact us OR Request a Quote today.